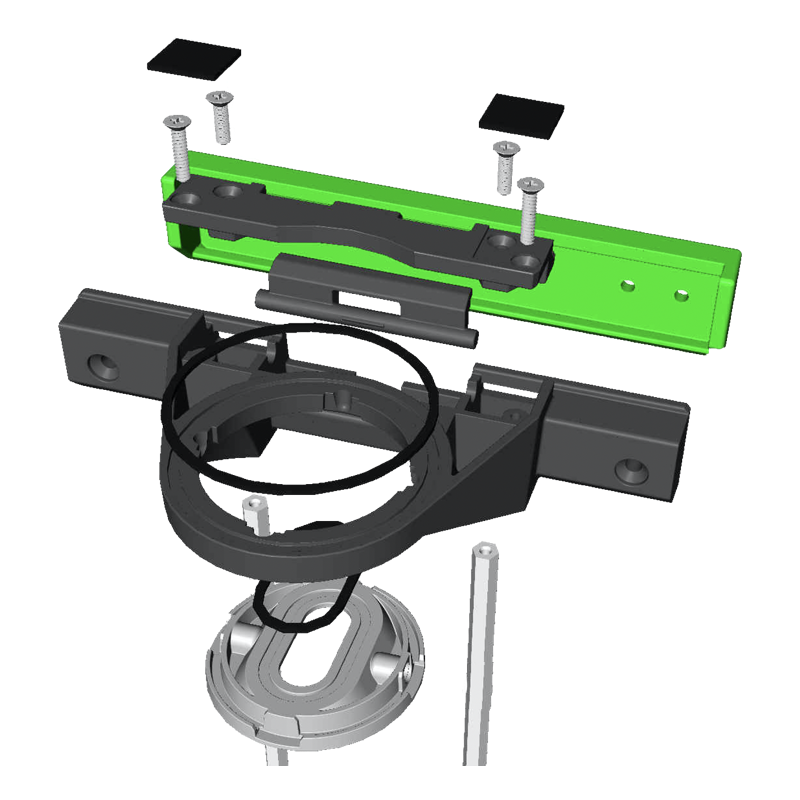

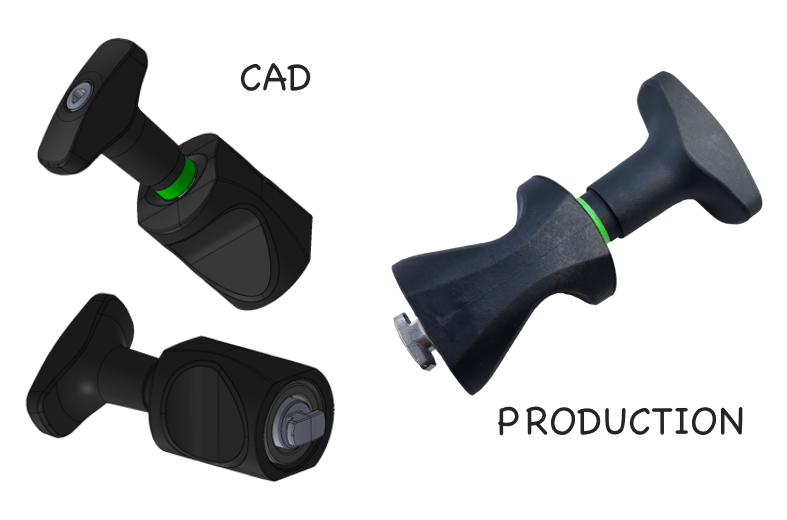

Clamping and latch systems

(Manufacture and Assembly to customer drawings)

Our client initially approached us to help them source some aluminium die castings for a latch system they needed for a new product they were developing. The client was a start up company which had raised significant funding to design develop and launch a world class reusable casing system to transport high value items safely all over the world. The plan was to do final product assembly in the UK whilst responsibly sourcing components from the most appropriate sub suppliers.

Our quotations proved to be particularly competitive for upfront tooling investment, offering savings of up to 50% compared to other European sources.

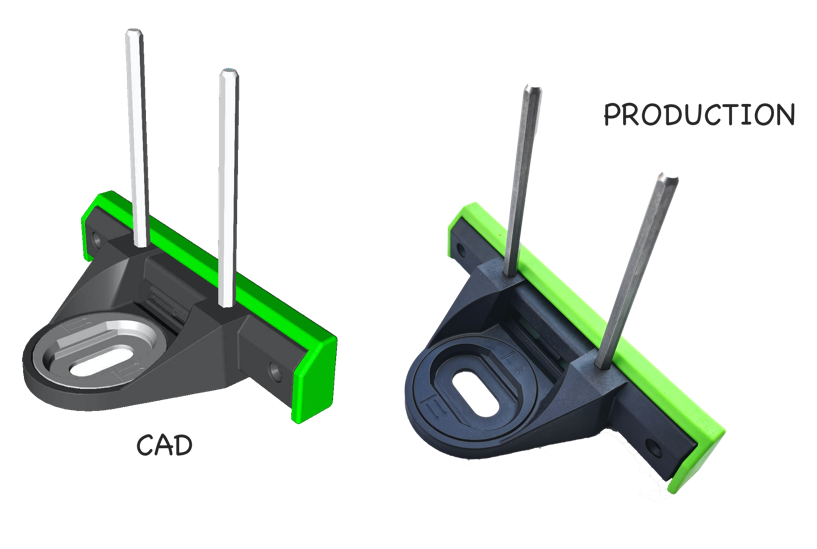

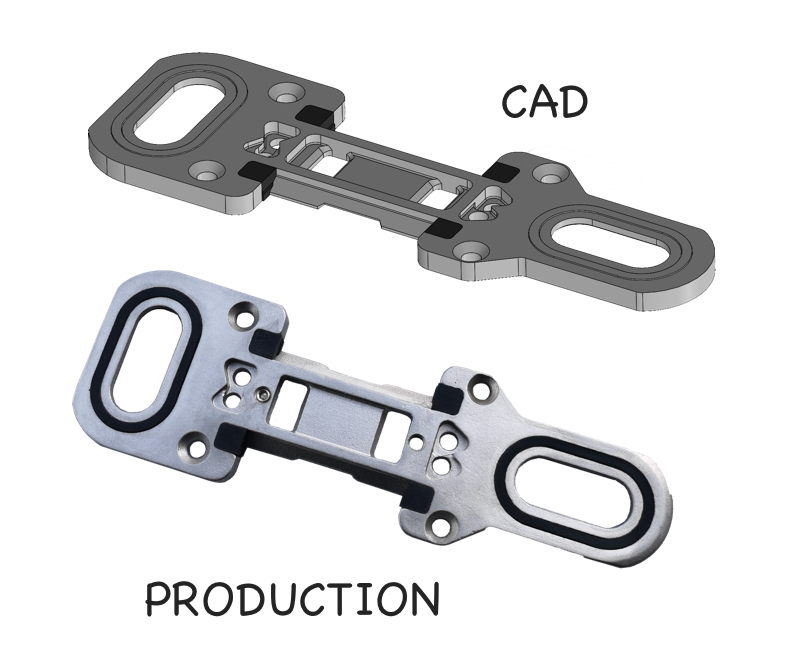

The client also appreciated our quick response to questions, added value in terms of technical advice on manufacturing feasibility, and ideas to solve some of their technical problems.

Challenges included:

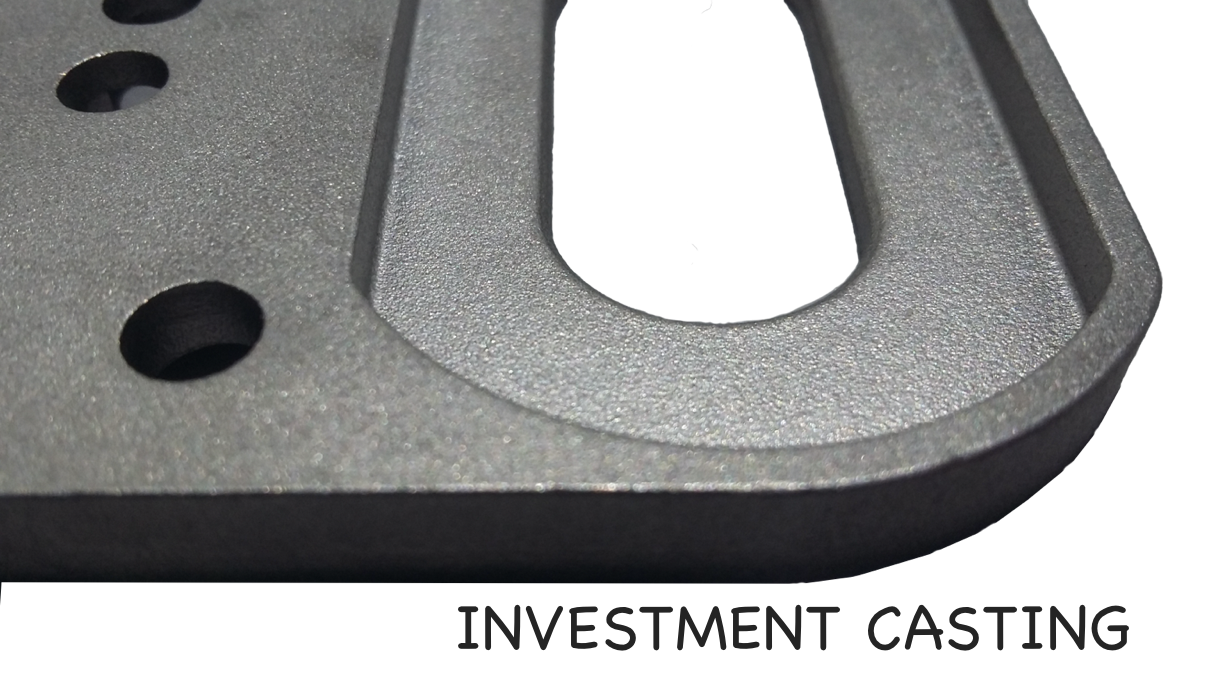

- Very high standards for cosmetic appearance

- Multiple late changes to their design

- Additional new products requiring short lead times and quick approvals

Soon we were asked to provide quotations on a range of products they were seeking to source including metal injection mouldings, plastic injection mouldings, investment castings and ultimately sub assembly of components.

In all we are now supplying over 30 different components for this project and we are pleased to have been part of the team to successfully bring this exciting new product into production.

The product is being received well into the industry it serves and has won prestigious awards including the ‘Best of the Best 2019’ distinction in the Red Dot Design Awards.